This is an excerpt from a thread in the internet with the discussion on running your car on water....

"You guys have been busy since the last time I was here! I've been reading the many comments posted and I have an observation. It seems many are people of absolutes, either you're mistaken or gullible, or they know themselves to be correct! If any post is potentially made by someone promoting bad information although the person believes the information to be accurate, then potentially all people are mistaken and this includes the skeptics of which I previously belonged.

No one has mentioned the public comment in a TV interview by the CEO of Ford Motor Company about 2 months ago that the hydroxy units show great promise to increase mileage and lower emissions for the 2012 year models. He was referring to the water electrolysis units many call HHO generators. He said that Ford Motor Company is considering the use of these on the 2012 year models which should be 48 volt systems. Not bad for junk technology is it? However, be advised Ford has been in contact with and working with another independent company that currently manufactures and sells these units, so this isn't anything ground breaking, just simple electrolysis of water.

I live in the United States, the state of Texas, and believe it or not there are many of us researching many different angles or fuel improvement devices. Most fuel improvement devices do not work as advertised or if they work there tends to be some negatives such as engine damage or incredible costs to purchase. In the U.S. we are conditioned to pay our electric bill, buy gasoline and smile really big when we pay our taxes! Every bit of this is good for the economy and makes for lots of jobs and progress. Spend all of your money and work hard to make more. That's what we do. Texas probably has at least 3 times more oil reserves than most people realize and it's somewhat unpatriotic to talk about improving mileage. If you talk about electric cars or zero petroleum fuel, you tend to offend most of those involved the lucrative oil industry. I wouldn't expect the entire world to just drop fossil fuels overnight. But I see no harm in studying the other possibilities even if on a small scale. If this offends you, then either you have a lot invested in fossil fuels or live a charmed life with no other serious problems!

I was noting something that dvldoc said, but no one has caught the fallacy in the statement. Instead of comparing apples to apples when he mentioned the trickle of HHO compared to a volume of air, this is an apples to oranges comparison (Yes, we call it HHO - we know it's actually two compounds, H2 & O2 made with electrolysis from another compound H2O which is made from the atoms of hydrogen and oxygen. No sense in revisiting the 6th grade chemistry to try and state the obvious just to point out how ignorant you think we are.). Had he compared the HHO (there I go again) to the trace of gasoline, diesel, propane or natural gas, this would have been a comparison of combustible fuel to combustible fuel, or apples to apples. Atmospheric air is mostly inert, with nearly 21% oxygen which is necessary for any combustion. The only part of the HHO that is remotely comparable to atmospheric air is the oxygen itself. On the comment that the amount of HHO compared to the amount of air being drawn into an engine is only a trace, it could be also stated that the amount of atomized gasoline being delivered compared to the large volume of air being drawn in is also just a trace even if a more significant trace. Here in Texas some of those big Cowboys can fart in the wind and it is more significant than you realize depending on where you are standing!

In a mechanically carbureted engine, the air/fuel mixture is set to balance the oxygen in the air to the appropriate amount of fuel being delivered so that the fuel can burn efficiently. Too much fuel without the proper amount of air leaves unburned fuel or a rich condition. Too much air caused a lean condition which in many cases can be destructive to engine parts such as valves or pistons depending on timing, compression and many other factors. If you increase the amount of combustible fuel without increasing the amount of air, or oxygen, you get a rich condition and fuel is wasted due to a lack of appropriate oxygen. Adding HHO to an already balanced air/fuel ratio does not upset the already set mechanical fuel delivery because the oxygen, O2, is already there in perfect proportions to match up with the hydrogen, H2, thereby eliminating the need for altering the carburetion adjustments on the engine. If you read where someone is adding only hydrogen to an engine to supplement mileage, in that case without the oxygen there is a need to increase the amount of air to ensure the hydrogen burns efficiently. Stating the extra oxygen is bad for the engine when introduced with the hydrogen is forgetting where that oxygen came from, and will return to. It came from water and will return to the original compound which is water. The HHO is it's own balance, and provided the engine was properly tuned prior to adding the HHO this balance does not affect the overall operation of the engine's fuel system. In the EFI systems this balance is adjusted and controlled by a processor that evaluates information from many sensory devices. In these systems the balance changes as the information from the sensors changes. Since the air/fuel ratio changes due to more efficient combustion when HHO is introduced, these systems do not work well with HHO without modifications. Here we are working hard to find a more simple way to get these systems to accept the HHO so we can install these on modern vehicles. So far the best way we've found to get these cars to work with HHO is to buy a special computer program to retune, or reset the settings using a laptop computer.

In my limited experience with hydrogen on demand from water for mileage, I've seen some people show me a system they bought off of the Internet or fabricated at home now mounted on their car. The system, poorly constructed and of a bad design, is improperly installed on the car. The owner then proudly states, "I'm getting 15% better mileage!" I think to myself, "If you're getting 15% better mileage with this junk, you're more talented than you appear to be!" Most of the information provided about these units is seriously suspect. I know that professional laboratories and testing facilities have tested these units, but they tend to be somewhat stingy in releasing good information to the public. In the meantime, and before some company like Ford produces something more efficient for us to evaluate, we are left building and testing these ourselves. I actually enjoy it.

Back to the negatives. No one mentioned anything about engine damage did they? Or did I miss that? People have damaged engines using these hydroxy units with corrosive electrolytes, like baking soda for one example. Also when not using a flashback presenter or bubbler others have had explosions and fires that damaged their vehicles, some of them trucks. I know of a couple of people here that have thought, "If a little HHO improved mileage 25%, then a lot of HHO should be much better!" They then burned up their alternator running excess amperage through their unit. I figured that one guy here in Texas can break even if he gets 40% better mileage and drives for another 2 years or 40,000 miles with no other accidents. Clearly he won't save enough money to pay for the expenses of buying the unit and then frying his alternator. Safety first, always install something like this with all considerations for avoiding engine damage or preventing an accident such as a fire or spilling water somewhere destructive.

I always take a calculator and figure what a person spends on fuel in one year of driving. This depends on how many miles/kilometers per year he or she drives and the average fuel consumption of that particular vehicle. If the vehicle consumes a lot of fuel, it's a good bet that even with moderate fuel savings the owner will see a quick return on their investment. However, if the vehicle is already getting good mileage, then the owner may have to drive 5 years, or more, just to pay for the money invested in the mileage device. It all depends on the vehicle.

I will close by saying this; I just cannot get the same mileage with the unit turned off as turned on. Clearly something is making an improvement in mileage. Both of my test cars are older antique cars that are carbureted, so no EFI to modify. With early hydroxy units of poor design the mileage increase was moderate to slight. As we've learned to make more HHO at very low amperage the mileage improvements are more significant. Consistently 35-45% better mileage than baseline before the unit was installed. On my 1967 VW Beetle when the engine is hot it vapor locks badly when the HHO unit is off and is hard to start. I have to run 93 octane with the unit turned off, runs great on 87 octane unit on. I can't imagine driving that car any distance without it. On this car I have so much experience and confidence in this latest unit I do not even have an on/off switch nor do I have an ammeter. Aside from a switch on the throttle that turns the unit off at engine idle, the unit runs, at low amperage continuously (4 amps or less depending on temperature). It does have an electronic pulser unit to control voltage and excess amperage however.

My engines are well tuned in superior mechanical condition for the most part. Both of my test cars have synthetic lubricants in the engine, transmission and differential which boosted mileage some. Tires are in good condition and air pressure checked often. I was already working hard to improve mileage prior to the HHO which allowed me some good mileage documentation. One test run to check mileage may be insufficient. You need an average of many tankfuls to get the proper information."

by: Art Nesmith

10.23.2009

10.18.2009

HHO Eureka!

These guys are funny... their first HHO experiment, of course I am discouraging Baking Soda and low grade metals since this makes those mucks which is Chromium Hexavalent - toxic.

Nevertheless, this is worth sharing.

10.14.2009

HYDROXY

HYDROXY

Stoichiometric Hydrogen and Oxygen Gas

1. GENERAL INTRODUCTION

The product of dissociation of water by electrolysis using the

patented Brown Gas generator is a completely safe compressed stoichiometric

hydrogen and oxygen gas mixture known as hydroxy (Brown's Gas). There is

no other method capable of producing such a gas. The novelty has been

patented in Australia and in other major countries around the world.

2. PROPERTIES OF HYDROXY

2.1 INTRODUCTION

Hydroxy (Brown's Gas) is a new product so there is no literature

describing the properties of this gas. Is has been a popular practice of

other investigators of the Brown's Gas Generator to ascribe to the gas the

properties of molecular hydrogen and oxygen gases in the proportion of 2:1.

Although this assumption seems very plausible it is incorrect. Hydroxy has

properties which are sufficiently different from the combined molecular

hydrogen and oxygen gas mixture to be significant in industrial and

commercial applications.

2.2 SAFETY OF HYDROXY

1. Hydroxy burns with a clear flame and the gas generator supplies the

gases at 280-320 kPa (40-50 psi).

2. The flame contains hydrogen and oxygen and no other elements so the

product of the burning is water.

3. The gas burns with a variety of nozzle sizes and can have a flame

length of up to 400mm.

4. The flame is extinguished by reducing the gas flow at the handle

and this is accompanied by a popping sound.

5. The New South Wales Department of Explosives has approved the

manufacture and use of the gas generation of hydroxy.

6. The flame is easily shown to be an exothermic reaction either with

water as an end product in some applications or dissociated

hydrogen and oxygen in other applications.

7. Hydroxy is safely stored, with little reassociation in the control

cell of the welder.

2.3 TEMPERATURE OF HYDROXY

The theoretical flame temperature is 4900 celsius but the temperature

changes with various applications (refer to #6 of 2.2).

The temperature available with hydroxy can be remarkably high, as, for

example, the flame is capable of drilling holes in high temperature

refractory products.

To illustrate the temperature range it is possible, using the same gas

flame pressure, to:

1. Succesfully weld aluminum sheet (700 celsius)

2. Sublimate tungsten (8000 celsius)

2.4 IMPLOSION OF HYDROXY

It is claimed that implosion, as a single reaction, only occurs with

hydroxy and is impossible with other substances.

1. A volume reduction occurs from 1900 to 1.

2. Detonation is achieved with a hot spark (other methods).

3. Only a low decibel "ping" accompanied the implosion of 3-4 litres

of hydroxy (even this noise level can be reduced).

4. The speed of detonation is greater then 4m/second.

5. When implosion occurs with a water interface no exhaust is

produced.

6. There is no contraction-expansion effect when hydroxy is imploded,

only a contraction.

7. Little heat is lost to the equipment in an implosion cycle.

2.5 ULTRA-HIGH VACUUM FROM HYDROXY

The new era of vacuum technology is possible using the implosion of

hydroxy.

1. The low cost of hydroxy production (340 1/Kwh) ensures a very

inexpensive method for producing an ultra-high vacuum.

2. There isn't another technique for producing a vacuum of such a high

purity in such a short period with very inexpensive equipment.

3.0 APLLICATIONS OF HYDROXY

The efficiency of DC power conversion to the thermal energy of the

produced hydrogen gas is 95%. But AC to DC conversion may be as high as

98% so the maximum efficiency of hydroxy production from AC supply is 93%.

Another important reason for using this electrolysis method for hydroxy

production is its ability to prodce the gas as required. So the inherent

problems of storage and loss by leakage are not relevant. The neutral

flame of hydroxy is important for welding and also as a clean heat source.

The following list fo suggestions for the use of hydroxy are

enumerated some salient properties are addended with a phrase or a simple

elaboration. The list is not exhaustive nor fully descriptive nor is it

meant to rank in order of importance. Naturally, many factors should be

considered when promoting a particular field of application because of the

possible economic, commercial and political disruption which could cause

readjustment at national levels.

3.1 LIST OF APPLICATIONS

1. Gas generator for welding, brazing, soldering.

(ex. AL, TIG. Lost costs, carbonizing flame, cutting, etc).

2. Special high temperature and thermal applications.

(ex. Ceramic surface, tiles, bricks, silica conversion, etc).

3. Atmospheric motor: stationary or transport

"A simple means has been found for making a vacuum, so atmospheric

pressure can be employed as a source of power."

(ex. pump, desalinator).

4. Coal to oil conversion: hydrogen production or new procedure.

(ex. drying coal, coal to graphite, waste gas conversion, etc).

5. Low energy (long time) - high energy (short time).

(ex. wind and other primary sources; low electrical - high thermal).

6. Aero applications: cheapest hydrogen production; turbo design (plus

vacuum).

4.0 CONCLUSION

It is worth emphasizing the five novelties presented by hydroxy:

1. Safety in the generation, storage, and use of the gas.

2. Inexpensive cost of production compared to other alternatives.

3. Very high temperature of the flame.

4. Implosion capability to trigger atmospheric pressure as a source of

power.

5. Ultra-high vacuum with simple equipment at low cost.

Could any other patent present so many innovative and developmental

possibilities as hydroxy with such a multitude of important applications?

R.B. Davis, PhD.

January 26, 1982

Stoichiometric Hydrogen and Oxygen Gas

1. GENERAL INTRODUCTION

The product of dissociation of water by electrolysis using the

patented Brown Gas generator is a completely safe compressed stoichiometric

hydrogen and oxygen gas mixture known as hydroxy (Brown's Gas). There is

no other method capable of producing such a gas. The novelty has been

patented in Australia and in other major countries around the world.

2. PROPERTIES OF HYDROXY

2.1 INTRODUCTION

Hydroxy (Brown's Gas) is a new product so there is no literature

describing the properties of this gas. Is has been a popular practice of

other investigators of the Brown's Gas Generator to ascribe to the gas the

properties of molecular hydrogen and oxygen gases in the proportion of 2:1.

Although this assumption seems very plausible it is incorrect. Hydroxy has

properties which are sufficiently different from the combined molecular

hydrogen and oxygen gas mixture to be significant in industrial and

commercial applications.

2.2 SAFETY OF HYDROXY

1. Hydroxy burns with a clear flame and the gas generator supplies the

gases at 280-320 kPa (40-50 psi).

2. The flame contains hydrogen and oxygen and no other elements so the

product of the burning is water.

3. The gas burns with a variety of nozzle sizes and can have a flame

length of up to 400mm.

4. The flame is extinguished by reducing the gas flow at the handle

and this is accompanied by a popping sound.

5. The New South Wales Department of Explosives has approved the

manufacture and use of the gas generation of hydroxy.

6. The flame is easily shown to be an exothermic reaction either with

water as an end product in some applications or dissociated

hydrogen and oxygen in other applications.

7. Hydroxy is safely stored, with little reassociation in the control

cell of the welder.

2.3 TEMPERATURE OF HYDROXY

The theoretical flame temperature is 4900 celsius but the temperature

changes with various applications (refer to #6 of 2.2).

The temperature available with hydroxy can be remarkably high, as, for

example, the flame is capable of drilling holes in high temperature

refractory products.

To illustrate the temperature range it is possible, using the same gas

flame pressure, to:

1. Succesfully weld aluminum sheet (700 celsius)

2. Sublimate tungsten (8000 celsius)

2.4 IMPLOSION OF HYDROXY

It is claimed that implosion, as a single reaction, only occurs with

hydroxy and is impossible with other substances.

1. A volume reduction occurs from 1900 to 1.

2. Detonation is achieved with a hot spark (other methods).

3. Only a low decibel "ping" accompanied the implosion of 3-4 litres

of hydroxy (even this noise level can be reduced).

4. The speed of detonation is greater then 4m/second.

5. When implosion occurs with a water interface no exhaust is

produced.

6. There is no contraction-expansion effect when hydroxy is imploded,

only a contraction.

7. Little heat is lost to the equipment in an implosion cycle.

2.5 ULTRA-HIGH VACUUM FROM HYDROXY

The new era of vacuum technology is possible using the implosion of

hydroxy.

1. The low cost of hydroxy production (340 1/Kwh) ensures a very

inexpensive method for producing an ultra-high vacuum.

2. There isn't another technique for producing a vacuum of such a high

purity in such a short period with very inexpensive equipment.

3.0 APLLICATIONS OF HYDROXY

The efficiency of DC power conversion to the thermal energy of the

produced hydrogen gas is 95%. But AC to DC conversion may be as high as

98% so the maximum efficiency of hydroxy production from AC supply is 93%.

Another important reason for using this electrolysis method for hydroxy

production is its ability to prodce the gas as required. So the inherent

problems of storage and loss by leakage are not relevant. The neutral

flame of hydroxy is important for welding and also as a clean heat source.

The following list fo suggestions for the use of hydroxy are

enumerated some salient properties are addended with a phrase or a simple

elaboration. The list is not exhaustive nor fully descriptive nor is it

meant to rank in order of importance. Naturally, many factors should be

considered when promoting a particular field of application because of the

possible economic, commercial and political disruption which could cause

readjustment at national levels.

3.1 LIST OF APPLICATIONS

1. Gas generator for welding, brazing, soldering.

(ex. AL, TIG. Lost costs, carbonizing flame, cutting, etc).

2. Special high temperature and thermal applications.

(ex. Ceramic surface, tiles, bricks, silica conversion, etc).

3. Atmospheric motor: stationary or transport

"A simple means has been found for making a vacuum, so atmospheric

pressure can be employed as a source of power."

(ex. pump, desalinator).

4. Coal to oil conversion: hydrogen production or new procedure.

(ex. drying coal, coal to graphite, waste gas conversion, etc).

5. Low energy (long time) - high energy (short time).

(ex. wind and other primary sources; low electrical - high thermal).

6. Aero applications: cheapest hydrogen production; turbo design (plus

vacuum).

4.0 CONCLUSION

It is worth emphasizing the five novelties presented by hydroxy:

1. Safety in the generation, storage, and use of the gas.

2. Inexpensive cost of production compared to other alternatives.

3. Very high temperature of the flame.

4. Implosion capability to trigger atmospheric pressure as a source of

power.

5. Ultra-high vacuum with simple equipment at low cost.

Could any other patent present so many innovative and developmental

possibilities as hydroxy with such a multitude of important applications?

R.B. Davis, PhD.

January 26, 1982

10.06.2009

Hydrogen boosters work. Here is how and why:

By George Vosper, P. Eng. June 1998. Hydrogen Injection -The technology of using hydrogen as a combustion enhancement in internal combustion engines has been researched and proven for many years. The benefits are factual and well documented.

Our own utilization of this technology. i.e. the hydrogen injection system, has also been tested and proven both by institutions and in hundreds of practical applications in road vehicles.

Here is a synopsis of a sampling of the research that has been done:

In 1974 John Houseman and D.J/Cerini of the Jet Propulsion Lab, California Institute of Technology produced a report for the Society of Automotive Engineers entitled "On-Board Hydrogen Generator for a Partial Hydrogen Injection Internal Combustion Engine". In1974 F.W. Hoehn and M.W. Dowy of the Jet Propulsion Lab, prepared a report for the9th Inter society Energy Conversion Engineering Conference, entitled "Feasibility Demonstration of a Road Vehicle Fuelled with Hydrogen Enriched Gasoline."

In the early eighties George Vosper P. Eng., ex-professor of Dynamics and Canadian inventor, designed and patented a device to transform internal combustion engines to run on hydrogen. He later affirms: "A small amount of hydrogen added to the air intake of a gasoline engine would enhance the flame velocity and thus permit the engine to operate with leaner air to gasoline mixture than otherwise possible.

The result, far less pollution with more power and better mileage." In 1995, Wagner, Jamal and Wyszynski, at the Birmingham, of University Engineering, Mechanical and Manufacturing, demonstrated the advantages of "Fractional addition of hydrogen to internal combustion engines by exhaust gas fuel reforming." The process yielded benefits in improved combustion stability and reduced nitrogen oxides and

hydrocarbon emissions.

Roy MacAlister, PE of the American Hydrogen Association states the "Use of mixtures of hydrogen in small quantities and conventional fuels offers significant reductions in exhaust emissions" and that "Using hydrogen as a combustion stimulant it is possible for other fuels to meet future requirements for lower exhaust emissions in California and an increasing number of additional states. Relatively small amounts of hydrogen can dramatically increase horsepower and reduce exhaust emissions."

At the HYPOTHESIS Conference, University of Cassino, Italy, June 26-29,1995, a group of scientists from the University of Birmingham, UK, presented a study about hydrogen as a fraction of the fuel. In the abstract of that study it stated: "Hydrogen, when used as a fractional additive at extreme lean engine operation, yields benefits in improved combustion stability and reduced nitrogen oxides and hydrocarbon emissions."

In the Spring of 1997, at an international conference held by the University of Calgary, a team of scientists representing the Department of Energy Engineering, Zhejiang University, China, presented a mathematical model for the process of formation and restraint of toxic emissions in hydrogen-gasoline mixture fueled engines.

Using the theory of chemical dynamics of combustion, the group elaborated an explanation of the mechanism of forming toxic emissions in spark ignition engines. The results of their experimental investigation conclude that because of the characteristics of hydrogen, the mixture can rapidly burn in hydrogen-gasoline mixture fueled engines, thus toxic emissions are restrained.

These studies and other research on hydrogen as a fuel supplement generated big efforts in trying to develop practical systems to enhance internal combustion engine performance. A few of them materialized in patented devices that didn't reach the level of performance, safety or feasibility that would allow them to reach marketing

stages.

California Environmental Engineering (CEE) has tested this technology and found reduction on all exhaust emissions. They subsequently stated: "CEE feels that the result of this test verifies that this technology is a viable source for reducing emissions and fuel consumption on large diesel engines."

The American Hydrogen Association Test Lab tested this technology and proved that:"Emissions test results indicate that a decrease of toxic emissions was realized." Again, zero emissions were observed on CO.

Northern Alberta Institute of Technology. Vehicle subjected to dynamometer loading in controlled conditions showed drastic reduction of emissions and improved horsepower.

We also conducted extensive testing in order to prove reliability and determine safety and performance of the components and the entire system. As a result of these tests, we achieved important breakthroughs as far as the designs of the components were concerned. We have since increased the hydrogen/oxygen production significantly. This has resulted in increased effectiveness on engine performance.

The results of these tests were able to confirm the claims made about this technology: the emissions will be reduced, the horsepower will increase and the fuel consumption will be reduced. From researching the Internet we also found the following information

To best describe how Hydrogen Enhanced Combustion works, we are providing this excerpt from a University Technical Report, written by Mr. GeorgeVosper, P.Eng.; ...a Hydrogen Generating System (HGS) for trucks or cars has been on the market for some time. Mounted on a vehicle, it feeds small amounts of hydrogen and oxygen into the engine's air intake. Its makers claim savings in fuel, reduced noxious and greenhouse gases and increased power. The auto industry is not devoid of hoaxes and as engineers are skeptics by training, it is no surprise that a few of them say the idea won't work. Such opinions, from engineers can't be dismissed without explaining why I think these Hydrogen Generating Systems do work and are not just another hoax.

The 2nd law of thermodynamics is a likely source of those doubts.

Meaning the law -would lead you to believe that it will certainly take more power to produce this hydrogen than can be regained by burning it in the engine. i.e. the resulting energy balance should be negative. If the aim is to create hydrogen by electrolysis to be

burned as a fuel, the concept is ridiculous.

On the other hand, if hydrogen shortens the burn time of the main fuel-air mix, putting more pressure on the piston through a longer effective power stroke, and in doing so takes more work out, then this system does make sense.

Does it work? Independent studies, at different universities, using various fuels, have shown that flame speeds increase when small amounts of hydrogen are added to air fuel mixes.

A study by the California Institute of Technology, at its Jet Propulsion Lab

Pasadena, in 1974 concluded: The J.P.L. concept has unquestionably demonstrated that the addition of small quantities of gaseous hydrogen to the primary gasoline significantly reduces CO and NOx exhaust emissions while improving engine thermal efficiency

A recent study at the University of Calgary by G.A. Karim on the effect of adding hydrogen to a methane-fuelled engine says ... The addition of some hydrogen to the methane, speeds up the rates of initiation and subsequent propagation of flames over the whole combustible mixture range, including for very fast flowing mixtures.

This enhancement of flame initiation and subsequent flame propagation, reduces the ignition delay and combustion period in both spark ignition and compression ignition engines which should lead to noticeable improvements in the combustion process and performance What happens inside the combustion chamber is still only a guess.

In an earlier explanation I suggested that the extremely rapid flame speed of the added hydrogen oxygen interspersed through the main fuel air mix, gives the whole mix a much faster flame rate. Dr. Brant Peppley, Hydrogen Systems Group, Royal Military College, Kingston, has convinced me that insufficient hydrogen is produced to have

much effect by just burning it. He feels that the faster burn is most likely due to the presence of nascent (atomic hydrogen and nascent oxygen, which initiate a chain reaction. I now completely agree. Electrolysis produces "nascent" hydrogen, and oxygen, which may or may not reach the engine as nascent. It is more probable that high temperature in the combustion chamber breaks down the oxygen and hydrogen molecules into free radicals (i.e. nascent). The chain reaction initiated by those free radicals will cause a simultaneous ignition of all the primary fuel. As it all ignites at once, no flame front can exist and without it there is no pressure wave to create knock.

Corrections Canada Bowden Alberta Institution

Corrections Canada tested several systems and concluded, "The hydrogen system is a valuable tool in helping Corrections Canada meet the overall Green Plan by: reducing vehicle emissions down to an acceptable level and meeting the stringent emissions standard set out by California and British Columbia; reducing the amount of fuel consumed by increased mileage." Additionally, their analysis pointed out that this solution is the most cost effective. For their research they granted the C.S.C Environmental Award.

The results of tests at Corrections Canada's, Bowden Alberta Institution and other independent tests reinforce the belief that combustion is significantly accelerated. They found with the HGS on, unburned hydrocarbons, CO and NO, in the exhaust were either eliminated or drastically reduced and at the same R.P.M. the engine produced more torque from less fuel.

Recently I took part in the highway test of a vehicle driven twice over the same 200- kilometre course, on cruise control, at the same speed, once with the system off and once with it on. A temperature sensor from an accurate pyrometer kit had been inserted directly into the exhaust manifold, to eliminate thermal distortion from the catalytic converter.

On average, the exhaust manifold temperature was 65°F lower

during the second trip when the Hydrogen Generating System was switched on. The fuel consumption with the unit off was 5.13253 km/li. and 7.2481 km/li. with it on, giving a mileage increase of 41.2% and a fuel savings attributable to the unit of 29.18% from the forgoing, the near absence of carbon monoxide and unburnt hydrocarbons confirms a very complete and much faster burn. Cooler exhaust temperatures show

that more work is taken out during the power stroke. More torque from less fuel at the same R.P.M. verifies that higher pressure from a faster burn, acting through a longer effective power stroke, produces more torque and thus more work from less fuel.

The considerable reduction in nitrous oxides (NOx} was a surprise. I had assumed that the extreme temperatures from such a rapid intense burn would produce more NO.,. Time plus high temperature are both essential for nitrous oxides to form. As the extreme burn temperatures are of such short duration and temperature through the remainder of the power stroke and the entire exhaust stroke, will, on average, be much cooler. With this in mind, it is not so surprising that less NOX is produced when the HGS is operating.

Assume a fuel-air mix is so lean as to normally take the entire power stroke (180°) to complete combustion. Educated estimates suggest the presence of nascent hydrogen and oxygen decreases the burn time of the entire mix by a factor of ten (10). If a spark advance of 4° is assumed, the burn would be complete at about 14° past top dead centre. Such a burn will be both rapid and intense. The piston would have moved less

than 2% of its stroke by the end of the burn, allowing over 98% of its travel to extract work. The lower exhaust manifold temperatures observed when the Hydrogen Generating System was in use can be viewed as evidence for this occurrence. Power consumed by this model of the electrolysis cell is about 100 watts. If an alternator efficiency of 60% is assumed, then 0.2233 horsepower will produce enough wattage.

Even on a compact car, a unit would use less than ¼ % of its engine's output, or about what is used by the headlights. The energy regained from burning the hydrogen in the engine is so small that virtually all of the power to the electrolyser must be considered lost. That loss should not, however, exceed V4%, so that any increase in the engine's thermal efficiency more than ¼ %, is a real gain.

An engineering classmate suggested a grass fire as a useful analogy to understand combustion within an engine. The flame front of a grass fire is distinct and its speed depends in part on the closeness of the individual blades. If grass is first sprayed with a small amount of gasoline to initiate combustion, then all blades will ignite almost in unison.

In much the same way, small amounts of nascent oxygen and hydrogen present in the fuel-air mix will cause a chain reaction that ignites all the primary fuel molecules simultaneously. Faster more complete burns are the keys to improving efficiency in internal combustion engines. Power gained from increased thermal efficiency, less the power to the electrolysis unit, is the measure of real gain or loss. It follows from the foregoing paragraph that even a modest gain in thermal efficiency will be greater than the power used by an electrolysis unit. The net result should therefore be positive.

Thus onboard electrolysis systems supplying hydrogen and oxygen to internal combustion engines, fuelled by diesel, gasoline or propane, should substantially increase efficiencies. While the auto industry searches for the perfect means of eliminating harmful emissions, consideration should be given to what these systems can do now, since the HGS considers reduction of harmful emissions even as the engine

ages. Almost all unburned hydrocarbons, CO and NO,, are eliminated.

Reducing hydrocarbons and CO causes a slight rise in the percentage of CO2 in the exhaust, but as less fuel is used, the actual quantity of CO2 produced is reduced by roughly the same ratio as the savings in fuel. In brief, noxious gas is almost eliminated and greenhouse gas is decreased in proportion to the reduction in fuel consumption.

Nothing I have learned so far has lessened my belief that the benefits of using electrolysis units to supply hydrogen to most types of internal combustion engines are both real and considerable.

For more information on the full report

http://www.panaceauniversity.org/Hydroxy%20Boosters.pdf

http://www.panacea-bocaf.org/hydroxygas.htm

http://pubs.acs.org/toc/enfuem/current

http://www.iahe.org/contactus.asp

Our own utilization of this technology. i.e. the hydrogen injection system, has also been tested and proven both by institutions and in hundreds of practical applications in road vehicles.

Here is a synopsis of a sampling of the research that has been done:

In 1974 John Houseman and D.J/Cerini of the Jet Propulsion Lab, California Institute of Technology produced a report for the Society of Automotive Engineers entitled "On-Board Hydrogen Generator for a Partial Hydrogen Injection Internal Combustion Engine". In1974 F.W. Hoehn and M.W. Dowy of the Jet Propulsion Lab, prepared a report for the9th Inter society Energy Conversion Engineering Conference, entitled "Feasibility Demonstration of a Road Vehicle Fuelled with Hydrogen Enriched Gasoline."

In the early eighties George Vosper P. Eng., ex-professor of Dynamics and Canadian inventor, designed and patented a device to transform internal combustion engines to run on hydrogen. He later affirms: "A small amount of hydrogen added to the air intake of a gasoline engine would enhance the flame velocity and thus permit the engine to operate with leaner air to gasoline mixture than otherwise possible.

The result, far less pollution with more power and better mileage." In 1995, Wagner, Jamal and Wyszynski, at the Birmingham, of University Engineering, Mechanical and Manufacturing, demonstrated the advantages of "Fractional addition of hydrogen to internal combustion engines by exhaust gas fuel reforming." The process yielded benefits in improved combustion stability and reduced nitrogen oxides and

hydrocarbon emissions.

Roy MacAlister, PE of the American Hydrogen Association states the "Use of mixtures of hydrogen in small quantities and conventional fuels offers significant reductions in exhaust emissions" and that "Using hydrogen as a combustion stimulant it is possible for other fuels to meet future requirements for lower exhaust emissions in California and an increasing number of additional states. Relatively small amounts of hydrogen can dramatically increase horsepower and reduce exhaust emissions."

At the HYPOTHESIS Conference, University of Cassino, Italy, June 26-29,1995, a group of scientists from the University of Birmingham, UK, presented a study about hydrogen as a fraction of the fuel. In the abstract of that study it stated: "Hydrogen, when used as a fractional additive at extreme lean engine operation, yields benefits in improved combustion stability and reduced nitrogen oxides and hydrocarbon emissions."

In the Spring of 1997, at an international conference held by the University of Calgary, a team of scientists representing the Department of Energy Engineering, Zhejiang University, China, presented a mathematical model for the process of formation and restraint of toxic emissions in hydrogen-gasoline mixture fueled engines.

Using the theory of chemical dynamics of combustion, the group elaborated an explanation of the mechanism of forming toxic emissions in spark ignition engines. The results of their experimental investigation conclude that because of the characteristics of hydrogen, the mixture can rapidly burn in hydrogen-gasoline mixture fueled engines, thus toxic emissions are restrained.

These studies and other research on hydrogen as a fuel supplement generated big efforts in trying to develop practical systems to enhance internal combustion engine performance. A few of them materialized in patented devices that didn't reach the level of performance, safety or feasibility that would allow them to reach marketing

stages.

California Environmental Engineering (CEE) has tested this technology and found reduction on all exhaust emissions. They subsequently stated: "CEE feels that the result of this test verifies that this technology is a viable source for reducing emissions and fuel consumption on large diesel engines."

The American Hydrogen Association Test Lab tested this technology and proved that:"Emissions test results indicate that a decrease of toxic emissions was realized." Again, zero emissions were observed on CO.

Northern Alberta Institute of Technology. Vehicle subjected to dynamometer loading in controlled conditions showed drastic reduction of emissions and improved horsepower.

We also conducted extensive testing in order to prove reliability and determine safety and performance of the components and the entire system. As a result of these tests, we achieved important breakthroughs as far as the designs of the components were concerned. We have since increased the hydrogen/oxygen production significantly. This has resulted in increased effectiveness on engine performance.

The results of these tests were able to confirm the claims made about this technology: the emissions will be reduced, the horsepower will increase and the fuel consumption will be reduced. From researching the Internet we also found the following information

To best describe how Hydrogen Enhanced Combustion works, we are providing this excerpt from a University Technical Report, written by Mr. GeorgeVosper, P.Eng.; ...a Hydrogen Generating System (HGS) for trucks or cars has been on the market for some time. Mounted on a vehicle, it feeds small amounts of hydrogen and oxygen into the engine's air intake. Its makers claim savings in fuel, reduced noxious and greenhouse gases and increased power. The auto industry is not devoid of hoaxes and as engineers are skeptics by training, it is no surprise that a few of them say the idea won't work. Such opinions, from engineers can't be dismissed without explaining why I think these Hydrogen Generating Systems do work and are not just another hoax.

The 2nd law of thermodynamics is a likely source of those doubts.

Meaning the law -would lead you to believe that it will certainly take more power to produce this hydrogen than can be regained by burning it in the engine. i.e. the resulting energy balance should be negative. If the aim is to create hydrogen by electrolysis to be

burned as a fuel, the concept is ridiculous.

On the other hand, if hydrogen shortens the burn time of the main fuel-air mix, putting more pressure on the piston through a longer effective power stroke, and in doing so takes more work out, then this system does make sense.

Does it work? Independent studies, at different universities, using various fuels, have shown that flame speeds increase when small amounts of hydrogen are added to air fuel mixes.

A study by the California Institute of Technology, at its Jet Propulsion Lab

Pasadena, in 1974 concluded: The J.P.L. concept has unquestionably demonstrated that the addition of small quantities of gaseous hydrogen to the primary gasoline significantly reduces CO and NOx exhaust emissions while improving engine thermal efficiency

A recent study at the University of Calgary by G.A. Karim on the effect of adding hydrogen to a methane-fuelled engine says ... The addition of some hydrogen to the methane, speeds up the rates of initiation and subsequent propagation of flames over the whole combustible mixture range, including for very fast flowing mixtures.

This enhancement of flame initiation and subsequent flame propagation, reduces the ignition delay and combustion period in both spark ignition and compression ignition engines which should lead to noticeable improvements in the combustion process and performance What happens inside the combustion chamber is still only a guess.

In an earlier explanation I suggested that the extremely rapid flame speed of the added hydrogen oxygen interspersed through the main fuel air mix, gives the whole mix a much faster flame rate. Dr. Brant Peppley, Hydrogen Systems Group, Royal Military College, Kingston, has convinced me that insufficient hydrogen is produced to have

much effect by just burning it. He feels that the faster burn is most likely due to the presence of nascent (atomic hydrogen and nascent oxygen, which initiate a chain reaction. I now completely agree. Electrolysis produces "nascent" hydrogen, and oxygen, which may or may not reach the engine as nascent. It is more probable that high temperature in the combustion chamber breaks down the oxygen and hydrogen molecules into free radicals (i.e. nascent). The chain reaction initiated by those free radicals will cause a simultaneous ignition of all the primary fuel. As it all ignites at once, no flame front can exist and without it there is no pressure wave to create knock.

Corrections Canada Bowden Alberta Institution

Corrections Canada tested several systems and concluded, "The hydrogen system is a valuable tool in helping Corrections Canada meet the overall Green Plan by: reducing vehicle emissions down to an acceptable level and meeting the stringent emissions standard set out by California and British Columbia; reducing the amount of fuel consumed by increased mileage." Additionally, their analysis pointed out that this solution is the most cost effective. For their research they granted the C.S.C Environmental Award.

The results of tests at Corrections Canada's, Bowden Alberta Institution and other independent tests reinforce the belief that combustion is significantly accelerated. They found with the HGS on, unburned hydrocarbons, CO and NO, in the exhaust were either eliminated or drastically reduced and at the same R.P.M. the engine produced more torque from less fuel.

Recently I took part in the highway test of a vehicle driven twice over the same 200- kilometre course, on cruise control, at the same speed, once with the system off and once with it on. A temperature sensor from an accurate pyrometer kit had been inserted directly into the exhaust manifold, to eliminate thermal distortion from the catalytic converter.

On average, the exhaust manifold temperature was 65°F lower

during the second trip when the Hydrogen Generating System was switched on. The fuel consumption with the unit off was 5.13253 km/li. and 7.2481 km/li. with it on, giving a mileage increase of 41.2% and a fuel savings attributable to the unit of 29.18% from the forgoing, the near absence of carbon monoxide and unburnt hydrocarbons confirms a very complete and much faster burn. Cooler exhaust temperatures show

that more work is taken out during the power stroke. More torque from less fuel at the same R.P.M. verifies that higher pressure from a faster burn, acting through a longer effective power stroke, produces more torque and thus more work from less fuel.

The considerable reduction in nitrous oxides (NOx} was a surprise. I had assumed that the extreme temperatures from such a rapid intense burn would produce more NO.,. Time plus high temperature are both essential for nitrous oxides to form. As the extreme burn temperatures are of such short duration and temperature through the remainder of the power stroke and the entire exhaust stroke, will, on average, be much cooler. With this in mind, it is not so surprising that less NOX is produced when the HGS is operating.

Assume a fuel-air mix is so lean as to normally take the entire power stroke (180°) to complete combustion. Educated estimates suggest the presence of nascent hydrogen and oxygen decreases the burn time of the entire mix by a factor of ten (10). If a spark advance of 4° is assumed, the burn would be complete at about 14° past top dead centre. Such a burn will be both rapid and intense. The piston would have moved less

than 2% of its stroke by the end of the burn, allowing over 98% of its travel to extract work. The lower exhaust manifold temperatures observed when the Hydrogen Generating System was in use can be viewed as evidence for this occurrence. Power consumed by this model of the electrolysis cell is about 100 watts. If an alternator efficiency of 60% is assumed, then 0.2233 horsepower will produce enough wattage.

Even on a compact car, a unit would use less than ¼ % of its engine's output, or about what is used by the headlights. The energy regained from burning the hydrogen in the engine is so small that virtually all of the power to the electrolyser must be considered lost. That loss should not, however, exceed V4%, so that any increase in the engine's thermal efficiency more than ¼ %, is a real gain.

An engineering classmate suggested a grass fire as a useful analogy to understand combustion within an engine. The flame front of a grass fire is distinct and its speed depends in part on the closeness of the individual blades. If grass is first sprayed with a small amount of gasoline to initiate combustion, then all blades will ignite almost in unison.

In much the same way, small amounts of nascent oxygen and hydrogen present in the fuel-air mix will cause a chain reaction that ignites all the primary fuel molecules simultaneously. Faster more complete burns are the keys to improving efficiency in internal combustion engines. Power gained from increased thermal efficiency, less the power to the electrolysis unit, is the measure of real gain or loss. It follows from the foregoing paragraph that even a modest gain in thermal efficiency will be greater than the power used by an electrolysis unit. The net result should therefore be positive.

Thus onboard electrolysis systems supplying hydrogen and oxygen to internal combustion engines, fuelled by diesel, gasoline or propane, should substantially increase efficiencies. While the auto industry searches for the perfect means of eliminating harmful emissions, consideration should be given to what these systems can do now, since the HGS considers reduction of harmful emissions even as the engine

ages. Almost all unburned hydrocarbons, CO and NO,, are eliminated.

Reducing hydrocarbons and CO causes a slight rise in the percentage of CO2 in the exhaust, but as less fuel is used, the actual quantity of CO2 produced is reduced by roughly the same ratio as the savings in fuel. In brief, noxious gas is almost eliminated and greenhouse gas is decreased in proportion to the reduction in fuel consumption.

Nothing I have learned so far has lessened my belief that the benefits of using electrolysis units to supply hydrogen to most types of internal combustion engines are both real and considerable.

For more information on the full report

http://www.panaceauniversity.org/Hydroxy%20Boosters.pdf

http://www.panacea-bocaf.org/hydroxygas.htm

http://pubs.acs.org/toc/enfuem/current

http://www.iahe.org/contactus.asp

10.01.2009

Subscribe to:

Posts (Atom)

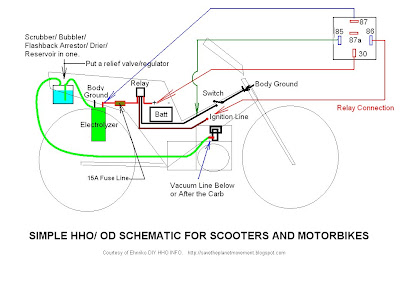

Simple Schematic for Scooters/ Motor Bikes

This is a very basic schematic for bikes.

HHO Chit Chat

Custom Search